The fine art of handcrafting a frame drum.

- bookofrhythms

- Jun 29, 2023

- 4 min read

Frame drums are played all over the world. This we know. They have a remarkable story tracing back through millennia with countless hands channeling their rhythms into the ether. They are still used in almost every musical genre one could imagine. In this journal entry, I thought to share some insights into how they're made; not cheap instruments—beautifully handcrafted, steam-bent drums that will last for generations to come. It all starts with timber selection.

Timber that is used for Steam & Lumber frame drums is sourced from locally salvaged street trees and the occasional trip to Tasmania, Australia. Tasmania is a wild and stunning region that is home to some of the most beautiful and long living trees in the world. Consideration and respect must be given when sourcing timbers from here, or anywhere for that matter. Throughout the generations, extensive logging has caused a near extinction of the magnificent Huon Pine (Lagarostrobos Franklinii), popular for its ease of working and resistance to rot. Huon Pine steam bends easily and is thus popular with boat builders and fine furniture makers.

It is important to consider the relationships created whilst traveling, sourcing timber and the milling process. Having a strong connection to the environment and relationships along the way, all become of part of the instrument itself.

Once the timber has been milled and sawn down into workable lengths, it is either stored and air dried or 're-hydrated' in water prior to the steam-bending process. For many years, timber has been bent to create boxes, sieves and all kinds of utensils through the use of steam or boiling water. It is a kind of alchemy that, for a short while only, softens the lignin in the timber allowing the fibers to move without splitting. It is an art form used today by instrument makers, fine furniture makers and boat builders. Timber for the frame drums is prepared with scarf joins prior to steaming and bending around prefabricated forms/jigs. Timbers used for Steam and Lumber frame drums are Blackwood (Acacia Melanoxylon), Spotted Gum (Corymbia Maculata), Pin Oak (Quercus Palustris), Huon Pine (Lagarostrobos Franklinii). Of course, there are several other species that occasionally find their way into the workshop.

The freshly steam-bent shells are then allowed to dry for two to three weeks depending on the season. If the shell comes of the jig with little or no resistance (Spring-back), the craftsperson can commence shaping; if the shell shows signs of spring-back, it's simply left to relax into it's new shape.

Shaping the frame drum is done by hand. Old compass planes, French handmade shaping files, spoke shaves gifted by old friends and hand saws with over a hundred years of stories are all employed to work their magic on each shell. It's quite a meditative process either set against the chosen music of the day or the creek flowing past the workshop's doors. There's an abundance of wildlife all around and I'm always in good company with our two Border Collies, Tilly (Puppy) and Sunny.

Following the glue-ups, shaping and sanding through the grits (120, 180, 240, 400), the timber shell slowly takes on the form of a musical instrument. The scarf join is carefully 'feathered' in with the shaping file and compass plane creating a rather stunning join to look at. Once the drum shell is perfect, Danish oil is applied before skin selection/ application. Frame drums at Steam & Lumber use either carefully selected goat skins or synthetic skins made by Remo (Mylar). Working with natural skins (Parchment) is a process that requires consideration— like the tree that was selected for it's timber, the skin too came from a living creature and thus needs respect, gratitude and for the artisan to be mindful at all times. It is a deeply personal process and a rather different mindset than when using Mylar.

Synthetic heads are difficult to apply and there are only a small handful of drum makers in the world that do it well, without the use of a metal hoop and external tuning lugs. It is a process achieved by heat, patience and for me personally, a gargantuan amount of practice.

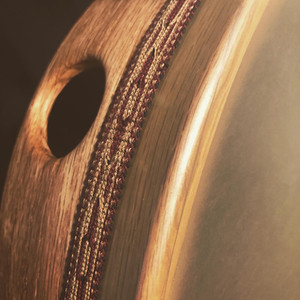

There are so many variations on a theme, when we discuss frame drums. Snares, chains, zills, jingles, bells and other additions to act as resonators and create dynamics. Most of the frame drums to be crafted at Steam & Lumber are tunable or non-tunable Tar drums and ZilliTar drums. The addition of zills to a larger drum gives the musician a wider variety of tones and textures. These can be grouped in two pairs like the Riqq (Riq/ Tef), or placed around the shell itself with customised sizes. All zills are hand-hammered in-house from high quality brass or bronze.

If you are looking for a beautifully handcrafted frame drum, an instrument made with the best quality materials and expertise, you should most definitely include a Steam & Lumber frame drum in your collection. Check out the online shop or contact us to discuss a custom build.

Be sure to join the newsletter to stay up to date with new drums, drum making courses or podcasts!

Comments